The AIRA RPH pH measurement robot allows for optimal utilization of the hams by automatic classification by measuring the pH level. The system combines an industrial robot in a hygienic configuration and an optimized probe for puncture and measuring the pH in addition to an automatic calibration station.

The total system consists of:

- Robot with hygienic protective cover

- Electrode to perform puncture

- Integrated pH meter

- Machine vision system

- Automatic calibration device system

- Carcass stabilization system

- Safety fence with secured entrance

pH measurement robot

The pH measurement robot is a system that combines an industrial six-axis robot with a hygienic configuration and an optimized tool to perform punctures. The pH measurement robot also includes an automatic calibration station. The entire system is equipped and protected to be installed in a room or chamber.

This pH measurement robot is specially designed for measuring the pH of pork. It is a fast and efficient way to test the pH of pork, and it can provide accurate results. This pH tester for pork is easy to use and it is very reliable. It is important to have pH testers for pork products to ensure food safety and quality control. This pH measurement robot can help you do just that!

The AiRA RPH pH measurement robot is CE approved and designed to meet the strictest demand on health and safety. The pH measurement robot can quickly and accurately measure the pH of pork, ensuring high hygiene levels and easy cleaning. The pH measurement robot is enclosed in a strong flexible protective cover with constant air flow inside and lightly overpressure, keeping the vital part of the robot clean and safe in the harsh environment. With the pH measurement robot, producers can quickly and easily test the pH of their pork products, ensuring high quality and safety standards.

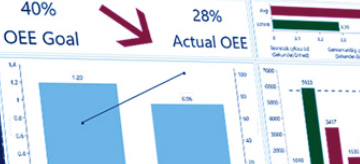

pH measuring pork ensures quality

pH measuring pork is important in order to ensure the quality of the meat. pH testing of pork can help ensure that the meat is safe to eat and of the highest quality. A pH testing robot can help a company save time and money by ensuring that the pork is properly tested before it is shipped out. pH testers for pork can also help a company avoid recalls and ensure that their products are of the highest quality.

If you're interested in learning more about our pH measuring pork solution, please don't hesitate to contact us. We'll be happy to discuss how you can benefit from our solution.

EN

EN

English

English

中文

中文

Español

Español

Deutsch

Deutsch

Français

Français