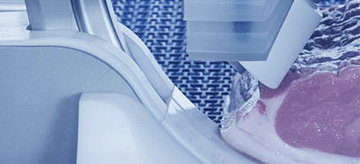

The automatic concept ensures uniform processing, accuracy and high-quality products.

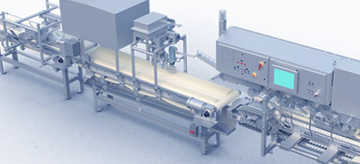

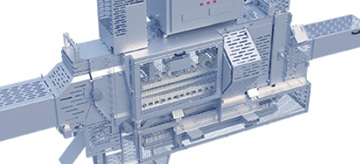

With the Frontmatec automated solutions, continuous operation on the primal cutting and deboning line is maintained, as the automatic machines and robot solutions are are synchronized with the line movement. During transfer of the middles on the robot conveyor, the middles are scanned by the 3D scanner, and specific cutting positions and a specific path is determined. Afterwards, the process is performed in a downward movement.

The Frontmatec concept is dynamic, as multiple automatic machines and robots can be fitted along the main conveyor of the primal cutting line, and the line movement of the deboning line. The automatic robots are all “plug and play”, and can operate in any type of new or existing deboning lines.

To ensure high hygiene levels, as well as easy efficient cleaning, the automatic chine bone saw is covered in a strong flexible cover with constant pressured air, keeping the vital parts of the robot clean and safe. Furthermore, the cutting conveyor is equipped with a belt lifting system.

The solution is approved for the food processing industry, which means it meets the strictest demands on health and safety and is designed in accordance with the EU and USDA regulations.

EN

EN

English

English

中文

中文

Español

Español

Deutsch

Deutsch

Français

Français